This machine is suitable for separating and cutting such various roll materials as BOPP, PET, CPP, CPE, PVC, aluminum foil and Paper Roll, etc. And can cut edge, separate and cut material according to different requirements during production.

Application:

This machine is suitable for separating and cutting such various roll materials as BOPP, PET, CPP, CPE, PVC, aluminum foil and Paper Roll, etc. And can cut edge, separate and cut material according to different requirements during production.

Feature

1. Automatic Thermal Paper Rolls Slitting Machine is equipped with PLC and HMI (touch screen) control system, all the parameters are displayed on the monitor.

2. Equipped with frequency inverter to control the motor.

3. Equipped with inverter motor for feeding, and one motor for automatic loading.

4. Equipped with Auto Tucker to tuck in the paper to cores automatically then rewinding.

5. Equipped with emergency switch.

6. All transmission rollers have been dynamic/static balance treated.

7. All the parts are treated by CNC processing to provide high precision.

Main Technical Specification

|

Model |

HWFQ-1300A |

HWFQ-1600A |

|

Suitable material |

PE,PP, BOPP, PET,CPP,Paper, PVC, etc |

|

|

Max. Unwind diameter |

850mm |

850mm |

|

Max. Unwind width |

100-1300mm |

100-1600mm |

|

Paper core inner diameter |

76mm |

76mm |

|

Max. cutting width |

40-1300mm |

40-1600mm |

|

Machine max.speed |

10-200m/min |

10-200m/min |

|

Max. slitting speed |

10-170m/min (perforation running speed different) |

|

|

Rewind diameter |

40-600mm×2 roll(depend on roll width) |

|

|

Main motor |

4kw |

5.5KW |

|

Accurate of adjustment |

±0.5mm |

±0.5mm |

|

Total power |

6KW |

7.5KW |

|

Gross weight |

2500KG |

3300KG |

|

Overall size |

3200×2200×1700mm |

3200×2400×1700mm |

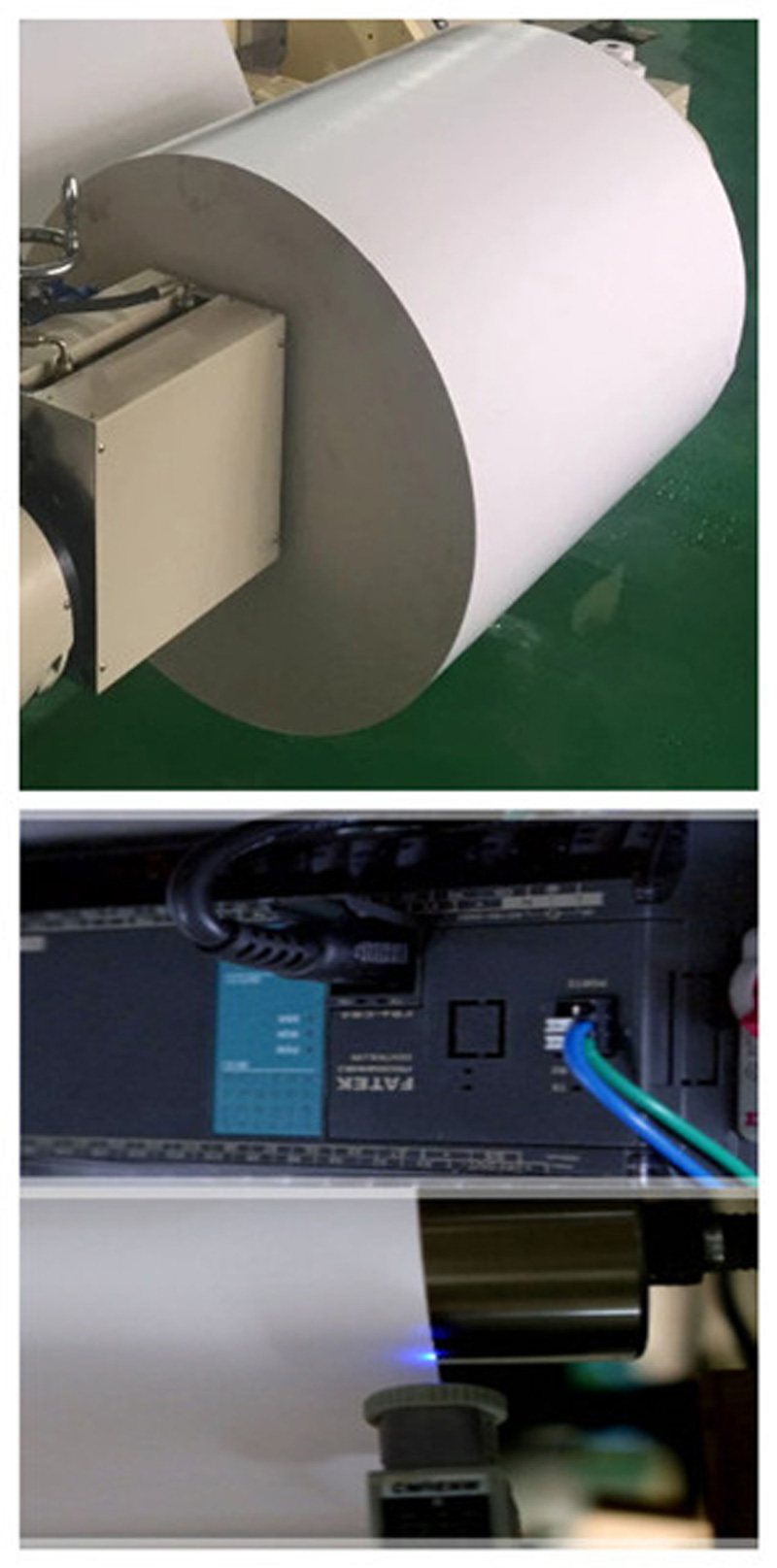

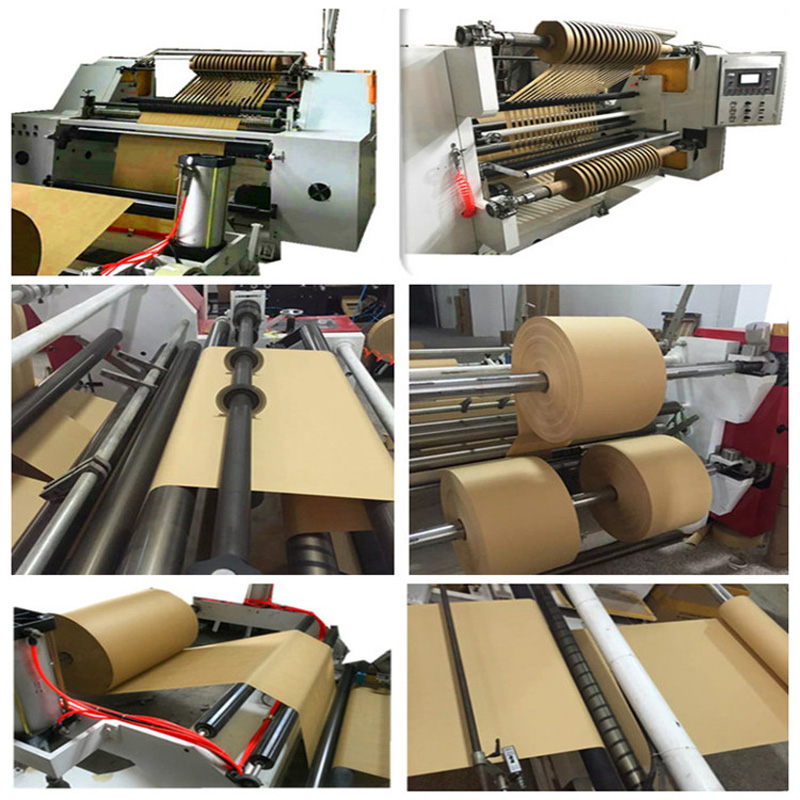

Details Photo:

Company Information:

Our Service:

1.More Professional service in Packaging and printing products exporting field

2.Better manufacture ability

3.Various payment term to choose:T/T,Western Union,L/C,Paypal

4.High quality/Safe material/Competitive price

5.Small order available

6.Quickly response

7.More safe and fast transport

8.OEM design for all customers

FAQ:

Q1. Payment Terms

A1. TT 30% down payment, 70% before shipment.

Q2. Delivery Time

A2. 15-30 working days from the receipt of the down payment.

Q3. Machine installation

A3.Hongwei could assign the technician to the place for the on-site installation if requested by the purchaser.

Q4. Technical Support

A4. Every machine is assigned by a specialist. The response is available within 12 hours while the solution for the troubleshooting is provided within 48 hours.

Q5. Demo and Testing

A5. Hongwei built a training center for the clients and employees to study the machines operation. You are welcome to visit our factory anytime for the machines’ demo. Furthermore, we could run the machine with the materials provided by you and help you achieve your business efficiently.

Les sacs en papier sont de plus en plus importants au 21e siècle car ces sacs sont 100% réutilisables, recyclables et biodégradables, tout en étant respectueux de l'...

La réduction du plastique est la principale préoccupation environnementale du gouvernement et des clients.L'utilisation des produits en papier au lieu des produits e...

Au cours de la période de grande utilisation des produits en plastique, le monde a vu les effets des déchets non biodégradables d'emballages en plastique sur l'envir...

Les sacs de transport en papier sont facilement recyclables par rapport aux sacs de transport en plastique et jouent un rôle important dans l'environnement. C'est un...

Un sac en papier est un sac en papier, généralement du papier kraft. Les sacs en papier sont couramment utilisés comme sacs à provisions, emballages. Les sacs en pap...